Infection Prevention: What is HHS’ 5 Zone/2 Zone Process?

Infection prevention doesn’t have to be complicated. Implementing widely accepted procedures, such as practicing proper hand hygiene, donning personal protective equipment (PPE), and using effective chemicals, minimize the risk of infection and cross-contamination.

HHS combines these tested practices with the 5 Zone/2 Zone (5Z/2Z) method to provide optimal results for our customers. This simple method has proven so effective that we now utilize it in other industries, including hospitality and senior living.

In this post, we’ll demonstrate why the 5 Zone/2 Zone (5Z/2Z) method works, highlight its key principles, and share the validation processes that enable us to keep our patients, staff, and visitors safe.

The 5Z/2Z Process

The 5Z/2Z process organizes patient room cleaning in a strategic sequence, minimizing the risk of cross-contamination and ensuring proper disinfection of all critical areas.

The Five Cleaning Zones (5Z)

Each zone is cleaned with at least one distinct cleaning cloth, but additional cloths may be needed within each zone if cleaning any heavily soiled surfaces.

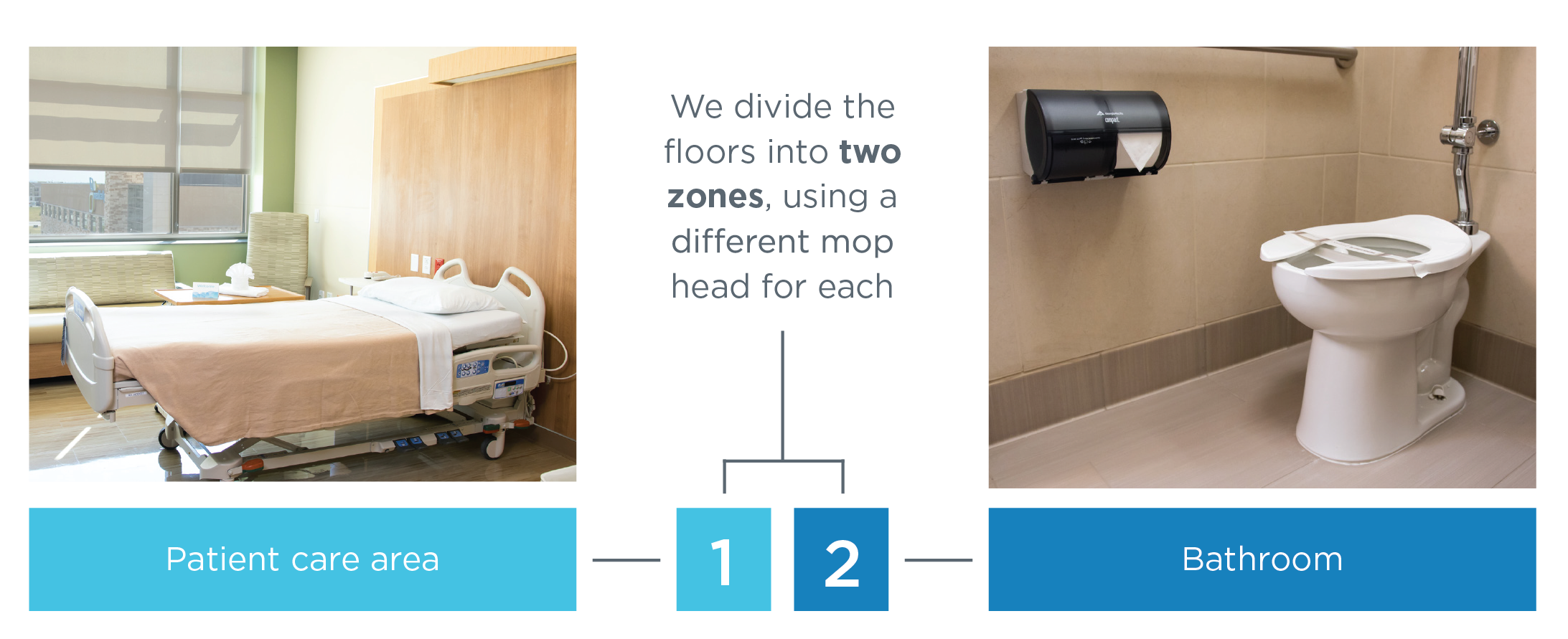

The Two Mopping Zones (2Z)

Once the room is clean from top to bottom and set up, we focus on floor care. Floors are divided into two zones, and a different mop head is used for each area.

Key Principles to Remember

Strategic Zone Order

Zones are organized to move from cleanest to dirtiest, reducing the risk of cross-contamination.

Apply Friction

Applying enough friction while using cleaning cloths and mops helps remove soil and pathogens from the surfaces and floors.

Don’t Double Dip

Once a cleaning cloth or mop has been used, do not return it to the clean disinfectant solution, as this will contaminate the solution.

Quality Assurance Practices

You can trust the 5Z/2Z method, but validating cleaning procedures is essential to any infection prevention program. HHS uses the following three practices to ensure the rooms meet HHS cleanliness standards, provide peace of mind to patients, and help elevate HCAHPS scores.

ATP Bioluminescence Testing (Quantitative)

Evidence-based testing with adenosine triphosphate (ATP), the energy molecule in living cells, delivers an exact measurement of a surface’s cleanliness. Managers swab a cleaned area and place the swab in a luminometer, a device that measures ATP.

Performance Indicators (PIs) (Qualitative)

Managers perform a daily visual inspection using PIs to guarantee adherence to standards and high-quality results. This also creates development opportunities for staff who need additional training and provides insight into trends and areas of improvement.

Fluorescent Marking Devices (Quantitative)

Managers use a marking tool in rooms and areas before cleaning. After cleaning, the manager will check the room — if a room is thoroughly cleaned according to HHS procedures, the fluorescent markings will not appear under the black light, providing immediate feedback on the room’s cleanliness.

Delivering Results with the HHS Approach

HHS believes in taking proven methods to the next level. In our 48 years of experience, we’ve found that a simple, practical approach can produce optimal results for our customers.

By layering the 5Z/2Z process on top of the proven infection prevention principles, HHS provides one more measure of protection against the risks of infection and cross-contamination, delivering results and peace of mind to both our customers and their patients.

Learn more about the HHS approach to infection prevention.